Katerra Product Design

C O M P A N Y

Katerra - Architecture & Construction

T O O L S

Solidworks, Keyshot, SLA Printers

R O L E

Industrial Design, Strategy, Product Development

KOVA is the official building products brand of Katerra, delivering the perfect balance of great design, consistent quality, and incomparable value.

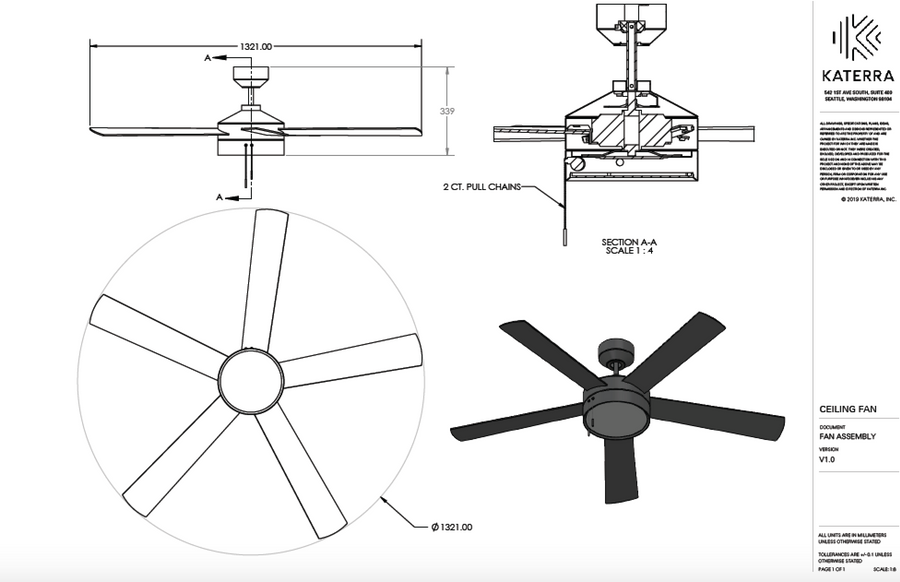

Ceiling fan

Installation Optimization

CLT installation

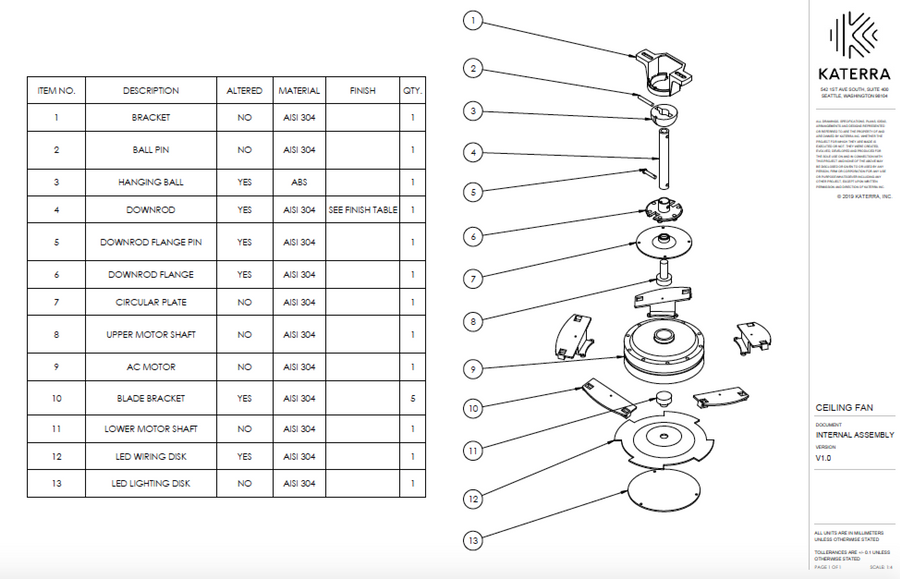

Minimize manufacturing steps.

Reduce Hardware and install time

Problem

Product Optimization

Low cost

Simple design

Effecient wiring

Design & Development

After eliminating failed options and reiterating on successful versions, the team decided on two options to move forward.

Full scale model test the feasibility of the finalized design.

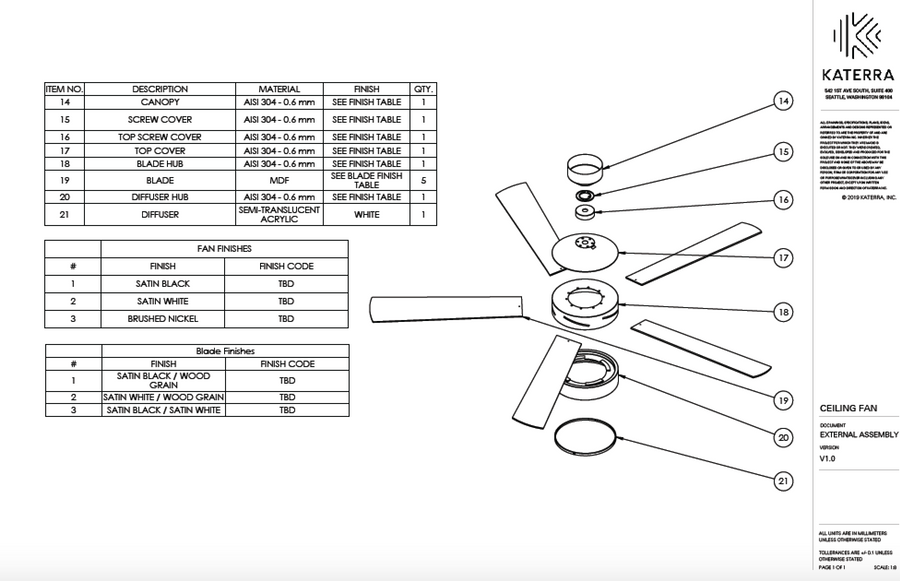

Three fan body finishes that would each have a different finish on each side of the fat blades.

Finishes

Research and Evaluation

After seaking out a documenting competitor product technical specifications, we evaluated how we would like to improve a fan beyond our current catalog fan.

What We Learned

To achieve the desired CFM for a 5 blade fan, the wattage would need to be more than our current catalog selection.

Discovery

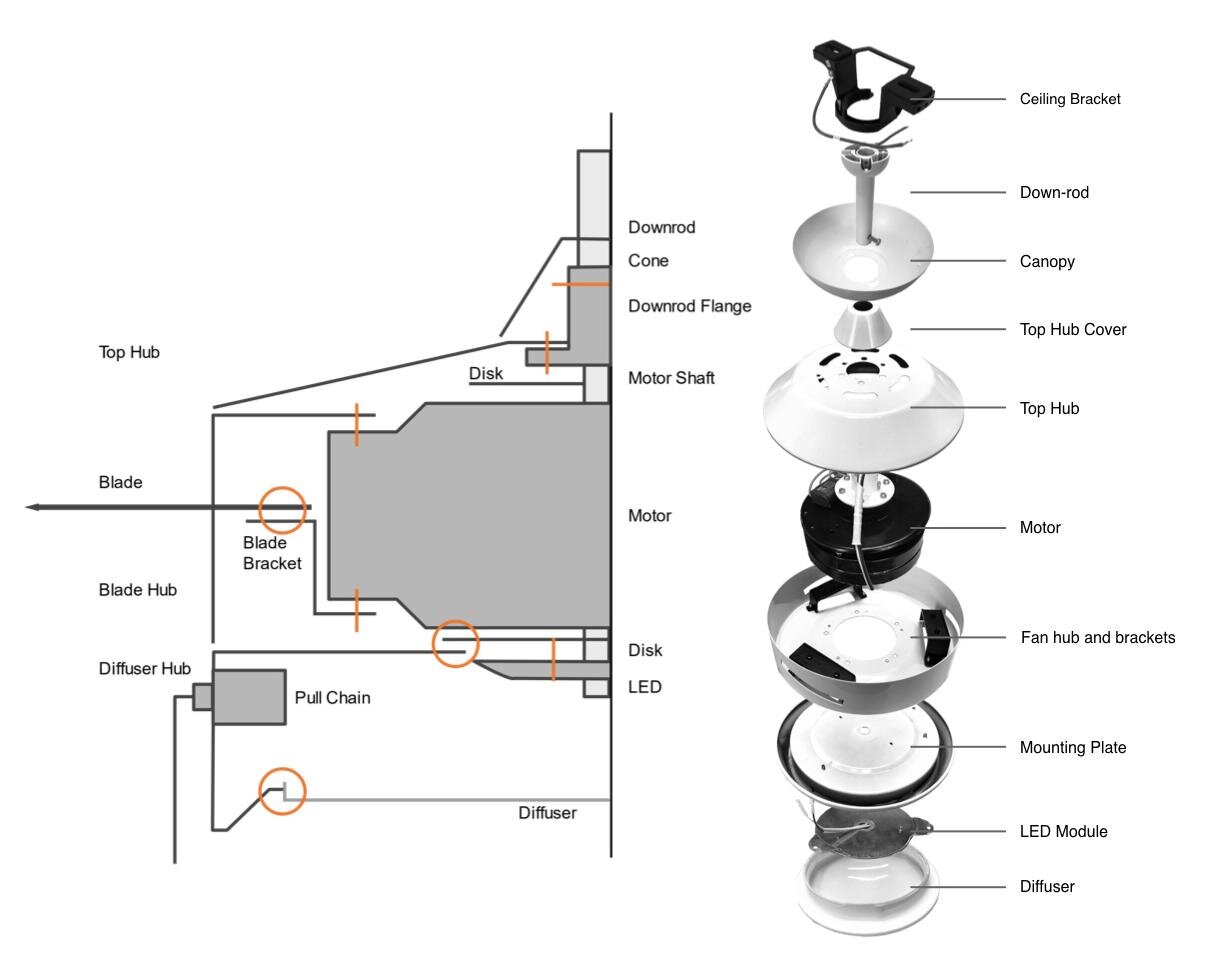

Disassembled four fans to evaluate each exterior and interior part to re-engineer more effecient ways of assembly.

Full-Scale Prototype

Bath Accessory System

Problem

Produce a well designed and cohesive bathroom accessories line effecientely manufactured and reduces installation time.

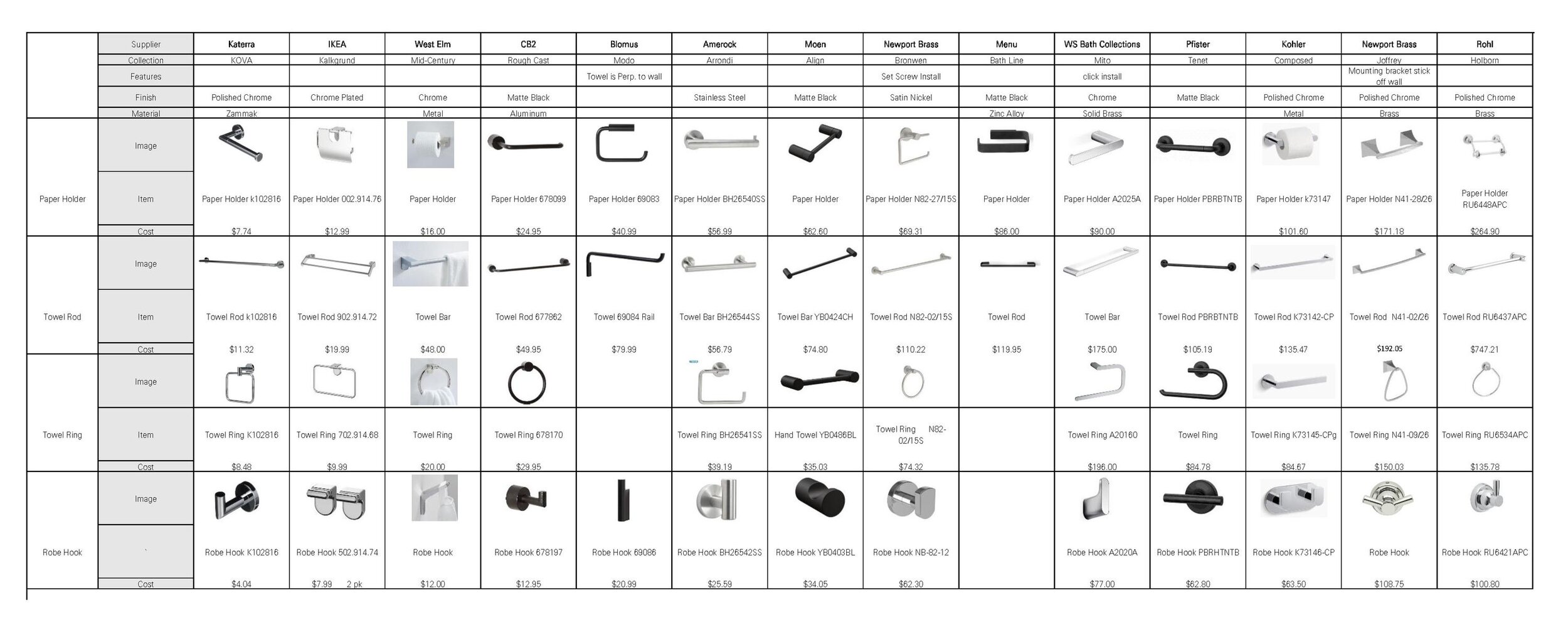

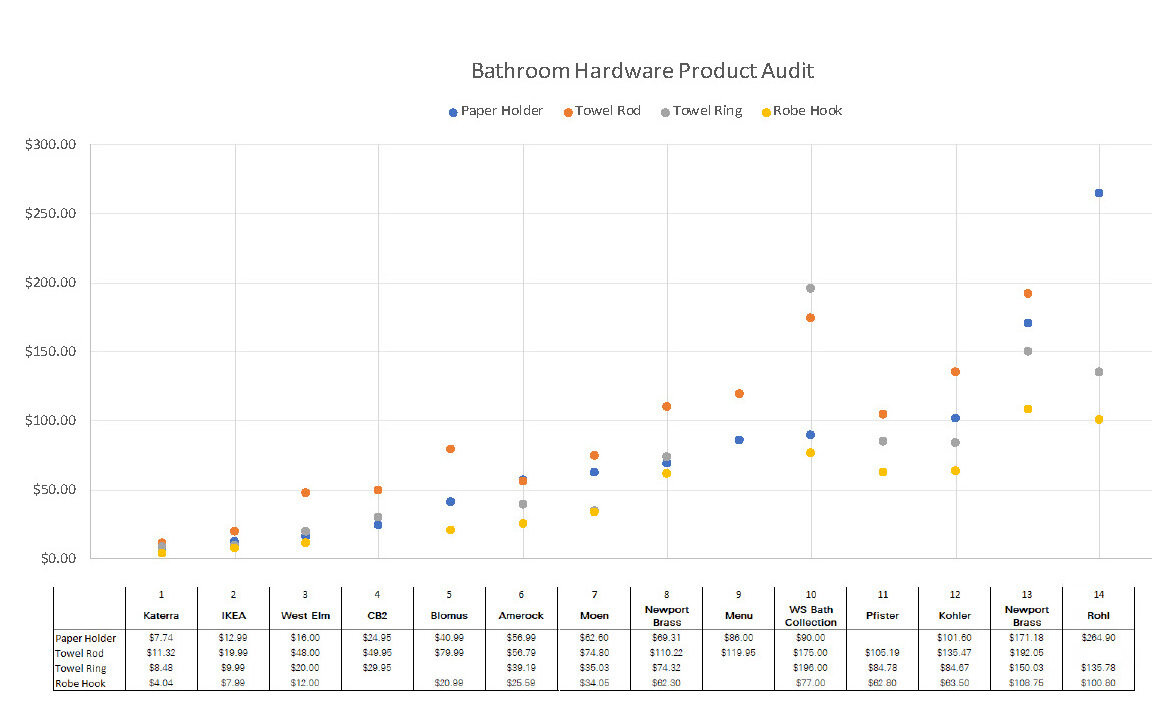

Competitor Product Audit

Conclusion

Ikea’s bath accessory pricing is Katerra’s closet Competitor.

There’s seemingly infinite styles of cabinet hardware at a low cost.

Not many options for style matching grab bars.

Inspiration

Conclusion

Sleek lines.

Simple geometry.

Fluidity between forms.

Textured surfaces.

Design Ethos Predictions

Design that reflects the pursuit of well being.

Design that promotes positive experiences.

Design that is sustainable.

Ideation

Shelving above accessories, cantilevered accessories, double TP rod, multi-rod towel bar, shelving accessory.

Modular Parts System

Like the Katerra Kova Select plumbing fixture line, a system of modular parts would be more cost effective than manufacturing each individual prduct.

Conclusion

Forms don’t always translate to ADA grab bars or cabinet pulls.

Square accessories aren’t cohesive with Kova Select Brand.

Kova Select plumbing fixture line doesn’t translate well to accessories

Multi Sensor Product Development

Problem

Product Optimization

Sensing

PIR motion, temperature, humidity, light, UV

Low cost

Less in cost than existing catalogue offering.

Good Design

Design to comply with KOVA design standards.

Installation Optimization

Dual Install

Mounted on either the ceiling or wall requiring a large FOV.

Gypsum & CLT

this product may be mounted to a secured junction box.

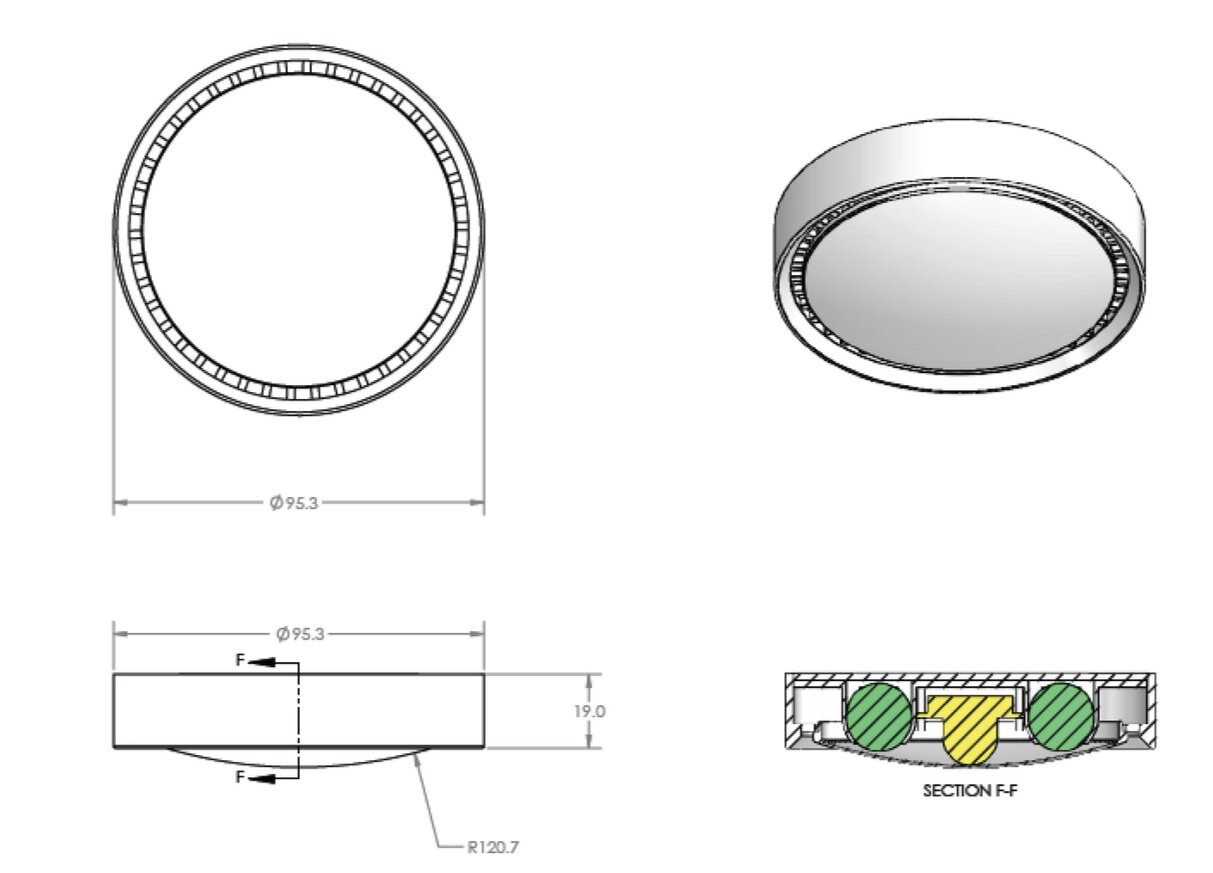

Competitor Product Audit

I started off by disassembling and researching competitor products to evaluate their forms, the organize the internal components, and create a robust information architecture of parts and features. The Project’s Manager and I decided that to achieve the form and the dual installation use, we would need a very specific form to the product. This meant that we would need to develop a non-standard PIR sensor and lens (passive infrared sensor). I knew nothing about PIR sensors other than there specs and capabilities but since Katerra has about 6000 employees throughout the world, I knew I would be able to find experts who could help.

Aesthetic and Functional Features

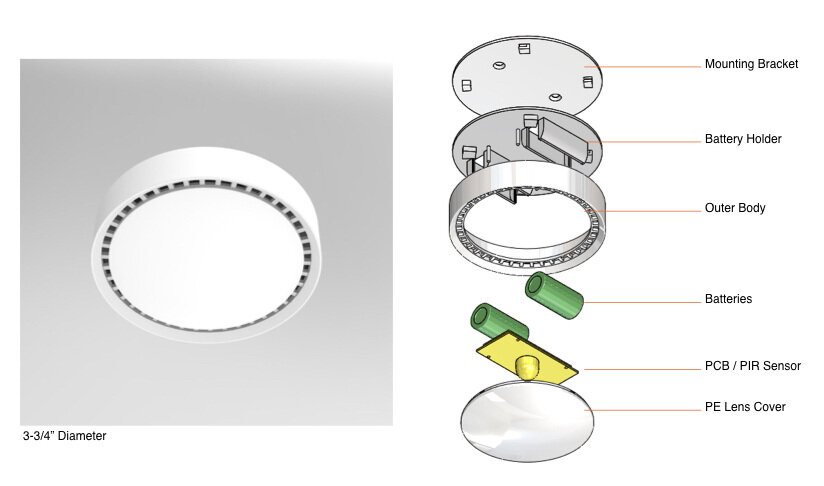

CFM is smooth white plastic to relate to standard ceiling or wall color.

Circular form that’s not out of the oridnary which might relate to a smoke alarm.

Sleek and low profile with minumum seams.

Conclusion

The form should not appear as a surveillance device.

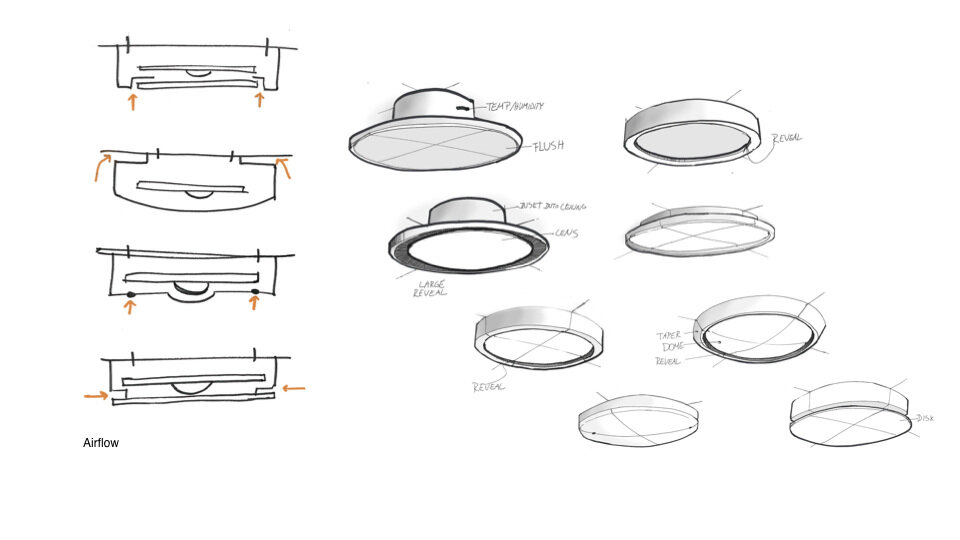

Design

While working with Katerra’s internal engineers and manufacturing in china, I developed a design that used a standard PIR sensor and PCB to dictate the overall size of the device.

Along with the optics engineer and our manufacturer in China, we were able to develop a PIR sensor and lens that gave the ability for the device to have a very flat profile like no other product on the market. This was not a quick journey as we went through many iterations of CAD models, annotated blue prints, physical prototypes, and testing for the device. I had to be comfortable making design adjustments during the prototyping phase knowing that we would need to throw ideas away or face some issues during the testing phase.

Adjustments with Manufacturing

A PIR lens that is flat as possible.

CRM124 rather than AA baterries.

3D printed prototype to better determine the design details.

3D printed model

Conclusion

I found that I was proud of how resourceful I could be by finding the proper experts and for pushing for a solution that first seemed impossible. At first, I felt a bit unsure about the things I didn’t know, but with some help I was able to learn a lot about electronics and optics to help launch a successful product.